What can we use for BigBoard connectors?

This one's from dinner with Nagle at pika last week. How would you upgrade snap circuits? They don't really encourage creativity (in his experience) beyond the circuits that they tell you how to build in the manual (even Nagle had a hard time coming up with more things he could build). How would you make a real electronics prototyping kit that kindergarteners could use?

Here's what we came up with. Temporary name: BigBoard.

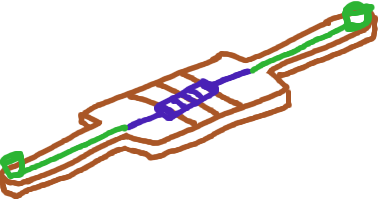

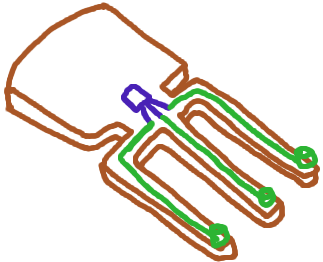

Brown is laser-cut lexan, thin, nonconductive surface. Blue is the actual electrical component (ideally there'd be another layer of plastic over this - a casing so small fingers don't get burnt). Traces and banana plug posts are in green. Each component has a velcro back, and you're meant to be able to stick it on a giant sheet of velcro (marked off with dots at regular intervals to give you a grid to eyeball things by - it looks almost like a very, very big protoboard, hence BigBoard). Shown below are examples for a resistor and transistor.

You get the idea and can probably imagine things like speakers, capacitors, LEDs, and so forth now (maybe even ICs eventually). Note a few things.

- You don't lose the look, feel, and shape of the actual components - they're not hidden, so kids will get used to seeing capacitors that look like capacitors, and so on. (I know, I know, surface-mount. Hush. We won't do that now.)

- Components are replaceable if they burn out.

- Banana plugs are stackable. You can have as many connections at each connection point as you want.

- The really big velcro sheet with regularly spaced dots looks like a protoboard. In fact, if you see a simple circuit made on a protoboard (maybe by a local friendly college student), you can recreate it with the BigBoard. And vice versa - someone could make a more permanent version of a BigBoard circuit that looks just like what's on the BigBoard, but smaller (important for young children who haven't gotten into the abstract thinking yet - it's hard to convey that thing X is isomorphic to thing Y to kids below a certain age).

This is a tiny snapshot of the excited discussion we had on what you could do with the BigBoard - we need to run off to the Fab Lab and make prototypes of it and try it out with kids, at this point. Two design issues for the beyond-prototype stage remain unresolved, though - so metabrain, please help us brainstorm!

- How do we make it cost less? Laser-cutting acrylic == $. Banana plugs and posts == expensive. If we come up with a different way to do connections between parts, that would save immense amounts of money - any ideas for connectors we can use? Ideas floated other than banana plugs so far: snap-buttons (though you'd lose the ability to make multiple connections at each connection point), mindstorms lego wire pieces (also expensive), jumper wires (small, sharp, and dangerous).

- What is the proper tradeoff between cost and repairability when it comes to safety features? How can we keep kids from getting shocked and burned, keep our components from getting shocked and burnt (and make it easy to replace them when we do), and keep things cheap? Example tradeoff: we could make gorgeous plastic cases to go over tiny breadboard-style sockets you could press the parts into; this would be safe and super-repairable, but cost a fortune. Or we could glob a big thing of epoxy over each part. Cheap, still pretty safe (I think - I don't know how well epoxy isolates things thermally), but very non-repairable.

Thoughts?